Battery Recycling - Lead

Closing the Loop in Lead Recycling

KANZA recovers lead from end‑of‑life lead‑acid batteries through a safe, controlled process—turning waste into high‑purity industrial commodities.

With an integrated value chain built for stewardship, purity, and traceability, we supply reliable material that supports a cleaner circular economy.

Collection & Compliance

Refining for Purity

Product Delivery

We Build

Pure Products

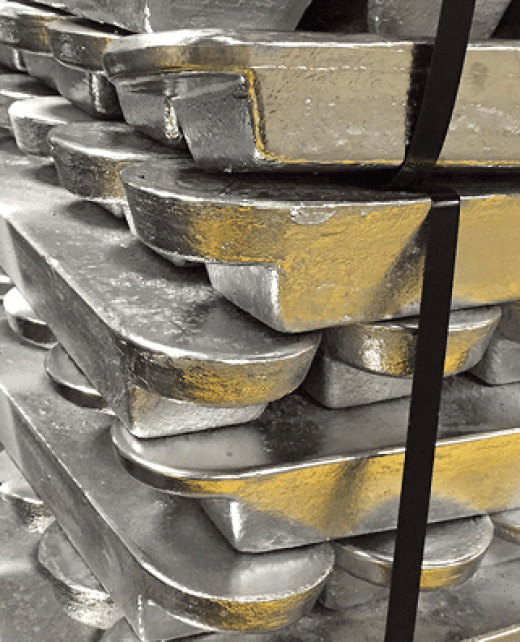

Refined Lead Ingots

KANZA produces refined lead ingots from end‑of‑life lead‑acid batteries through a controlled, closed‑system process.

Our integrated operations deliver consistent purity, reliable supply, and full traceability for industrial use.

Industrial Applications

KANZA’s refined lead ingots are used across essential industries where consistent purity and reliable performance matter. Our integrated recovery and refining process ensures dependable supply for both standard and customised requirements.

Battery manufacturing

Cable sheathing

Construction & building materials

Radiation shielding

Ammunition & defense use-cases (as per compliance)

Industrial lead weights & general engineering

Why Choose KANZA Lead Ingots

KANZA’s refined lead ingots are produced through a controlled, integrated process that prioritizes purity, safety, and consistent output for industrial use.

Every batch is managed with quality controls to ensure reliable, repeatable performance and compliance-led supply.

High purity and consistent chemistry

Dross-minimized, clean finish (as per specification)

Reliable, repeatable quality across batches

Traceable supply through an integrated value chain

Customised compositions available to match customer impurity limits

Safe handling and compliance-focused operations

Built on Consistency & Control

Quality is embedded into every stage of KANZA’s lead recycling and refining process—from compliant intake to final casting—so each batch meets defined chemical and performance targets.

Our integrated value chain enables strict process control, repeatable results, and full traceability for industrial customers.

| Element | Symbol | Limit (%) |

|---|---|---|

| Antimony | Sb | 0.001 (max) |

| Arsenic | As | 0.001 (max) |

| Tin | Sn | 0.001 (max) |

| Copper | Cu | 0.001 (max) |

| Bismuth | Bi | 0.015 (max) |

| Iron | Fe | 0.001 (max) |

| Nickel | Ni | 0.001 (max) |

| Silver | Ag | 0.003 (max) |

| Zinc | Zn | 0.001 (max) |

| Calcium | Ca | 0.0005 (max) |

| Sulphur | S | 0.0005 (max) |

| Aluminium | Al | 0.0005 (max) |

| Selenium | Se | 0.0005 (max) |

| Cadmium | Cd | 0.0005 (max) |

| Tellurium | Te | 0.0010 (max) |

| Lead | Pb | 99.970 (min) |

Made to Your Specification

Lead Alloys

KANZA manufactures customised lead alloys engineered to match specific chemistry, impurity limits, and performance requirements.

Our integrated recycling and refining chain ensures uniform alloying, consistent quality, and full traceability for demanding industrial applications.

Calcium Lead Alloy

Antimony Selenium Lead Alloy – 2.5

Antimony Lead Alloy – 3.0

Antimony Lead Alloy – 4.5

Copper Lead Alloy

Tin Lead Alloy

Lead Alloy E & E ½

Lead Alloy Applications

KANZA’s lead alloys are engineered for critical uses where controlled chemistry and consistent performance directly impact product life and safety.

We support standard and customised alloy grades for battery and cable industries, along with specialised industrial applications.

- Battery grids & plates (Automotive, Tubular, SMF, VRLA)

- Power cable sheathing & sleeves (insulation protection and long service life)

- Chemical equipment parts and lead pipes (corrosion-resistant use-cases)

- Solder and specialty alloy formulations (tin-rich grades as required)

- Industrial components and engineered parts requiring defined mechanical properties

High Quality

Lead Alloy

Quality is managed through defined process controls, melt handling discipline, and batch verification to ensure chemistry remains within the agreed specification limits. Customer-specific impurity thresholds and composition windows can be supported for repeat orders and long-term supply programs.