Copper Products

Powering Progress with Recycled Copper

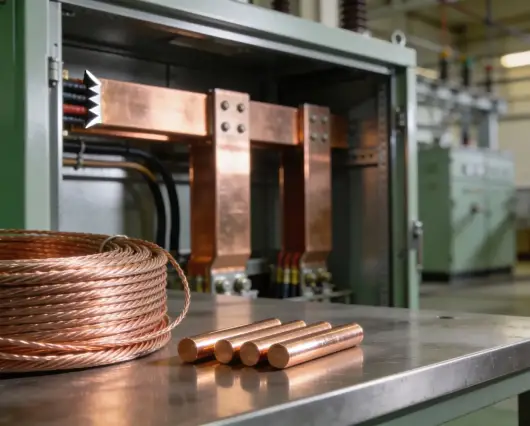

KANZA produces high-grade copper rods from quality recycled inputs, engineered for conductivity, ductility, and dependable industrial performance.

With in-house conversion capability, we supply copper products that support regional infrastructure while strengthening a cleaner circular economy.

Material Recovery & Casting

Drawing & Stranding

Product Delivery

We Build

Quality Conductors

Copper Rods

KANZA produces high‑grade copper rods from quality recycled inputs, engineered for strong conductivity and ductility.

With integrated recovery and advanced manufacturing, we deliver reliable, traceable copper products for real industrial and infrastructure use.

Industrial Applications

KANZA’s copper products—including high‑grade copper rods and drawn & stranded copper wires—support critical infrastructure where conductivity, durability, and consistent specifications matter.

Our integrated manufacturing ensures reliable supply for both standard and customised requirements.

- Wire & cable production (feedstock-grade copper rods)

- Electrical conductors & stranded cables for power distribution

- Construction wiring and infrastructure projects

- Industrial equipment and general electrical applications requiring dependable conductivity

Why Choose KANZA Copper Products

KANZA’s copper rods and wires are produced through an integrated process that prioritizes conductivity, consistent output, and reliable industrial performance.

From casting to drawing and stranding, every batch is managed with quality controls to ensure repeatable results and traceable supply.

- High conductivity and consistent material properties

- Copper rods engineered for wire & cable production (IACS-focused performance)

- Reliable, certified drawn & stranded copper wires

- Repeatable quality across batches with controlled in-house processing

- Traceable supply through an integrated value chain

- Custom sizes and gauges available to match project needs

Built on Consistency & Control

Quality is embedded into every stage of KANZA’s copper recovery and manufacturing—from controlled processing and casting to drawing and stranding—so every batch meets defined conductivity and performance targets.

Our integrated value chain enables strict process control, repeatable results, and full traceability for industrial customers.

We Build

Pure Products

Refined Copper Ingots

KANZA delivers refined copper ingots engineered for industrial reliability—produced through an integrated value chain that prioritizes purity, repeatability, and traceable supply.

Our controlled operations turn recycled copper feedstock into consistent, high‑quality metal suitable for demanding electrical and manufacturing applications.

Industrial Applications

KANZA’s refined copper ingots are supplied as a consistent, high‑quality input for industries where conductivity and repeatable performance are critical.

Our integrated recovery and processing model supports dependable availability and traceable supply for downstream manufacturing.

Copper rod production (feedstock for further processing).

Wire and cable manufacturing (as upstream metal for conductors).

Electrical and power infrastructure components where stable copper quality matters.

General engineering and metal fabrication requiring consistent copper chemistry.

Why Choose KANZA Copper Ingots

KANZA’s refined copper ingots are produced through a controlled, integrated process designed to deliver consistent chemistry, dependable performance, and stable industrial supply.

With full control across recovery, processing, and output, KANZA supports traceable, repeatable quality for demanding downstream manufacturing and infrastructure use.

High purity and consistent chemistry.

Low-impurity, clean finish (as per specification).

Reliable, repeatable quality across batches.

Traceable supply through an integrated value chain.

Customised compositions available to match customer impurity limits.

Compliance-focused operations and controlled handling standards.

QUALITY ASSURANCE

Quality assurance is embedded into KANZA’s operations to ensure every batch is consistent, traceable, and aligned with industrial requirements and compliance expectations.

With full control across an integrated value chain, KANZA maintains repeatable outcomes—backed by disciplined process control and secure material flow from input to finished metal.