From Material to Market

KANZA bridges recovery and real industrial demand through controlled trading and processing—delivering specification‑matched non‑ferrous material streams with consistent quality and traceability.

We don’t position this as manufacturing; our focus is on compliant sourcing, disciplined processing controls, and reliable dispatch so every lot meets defined customer requirements.

Material Grading & Segregation

Quality Control & Traceability

Dispatch & Supply Reliability

Battery Recycling – Lead

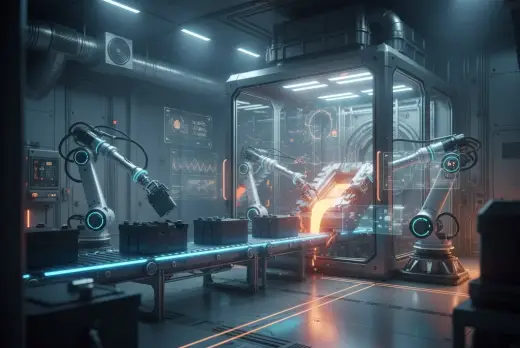

KANZA handles lead‑bearing battery streams through a controlled, compliance‑focused workflow designed for safe handling, consistent quality outcomes, and full traceability.

Our integrated value chain supports secure material flow—from collection and intake controls to processing and verified output targets aligned with industrial requirements.

Safe, compliant intake and handling of lead‑acid battery streams.

Controlled processing pathways to maximize recovery while minimizing environmental impact.

Batch traceability and quality targets aligned with customer specifications.

Copper Products

KANZA manages copper material streams through controlled trading and processing workflows designed to deliver consistent specs, reliable lots, and full traceability for industrial buyers.

Operational controls focus on material evaluation, segregation, contamination control, and quality verification—so customers receive predictable copper inputs for downstream use.

Supplier/lot assessment and grading to align incoming copper with required specifications.

Processing and finishing controls (cleaning, sizing, and surface/condition checks as applicable) to improve consistency and usability.

Quality assurance checkpoints and documented traceability for repeatable, compliant supply.

Aluminium Products

KANZA manages aluminium material streams through structured trading and processing workflows designed to deliver consistent lots, predictable specifications, and dependable supply for industrial buyers.

Operational controls emphasize material grading, segregation, contamination control, and documented traceability—so each shipment aligns with customer requirements and compliance expectations.

Supplier and lot evaluation to classify aluminium streams by grade and intended use-case.

Controlled segregation and processing to improve cleanliness and consistency (as applicable to the material type).

Quality assurance checkpoints and lot traceability to support repeatable, specification-matched supply.

Plastic Products

KANZA supports circular plastics streams through controlled polymer recovery and processing, focusing on clean material separation, consistent output quality, and traceable lots for industrial reuse.

This vertical is designed to “close the plastic loop” by supplying recovered polymer material as a reliable raw input that helps reduce reliance on virgin resins.

Controlled recovery of non‑metal fractions (including polymer streams) with safe handling and compliance-first operations.

Washing/processing workflows (as applicable) to achieve high‑purity recycled polymer output suitable for reuse.

Lot consistency and traceability controls to support repeatable supply for downstream buyers.